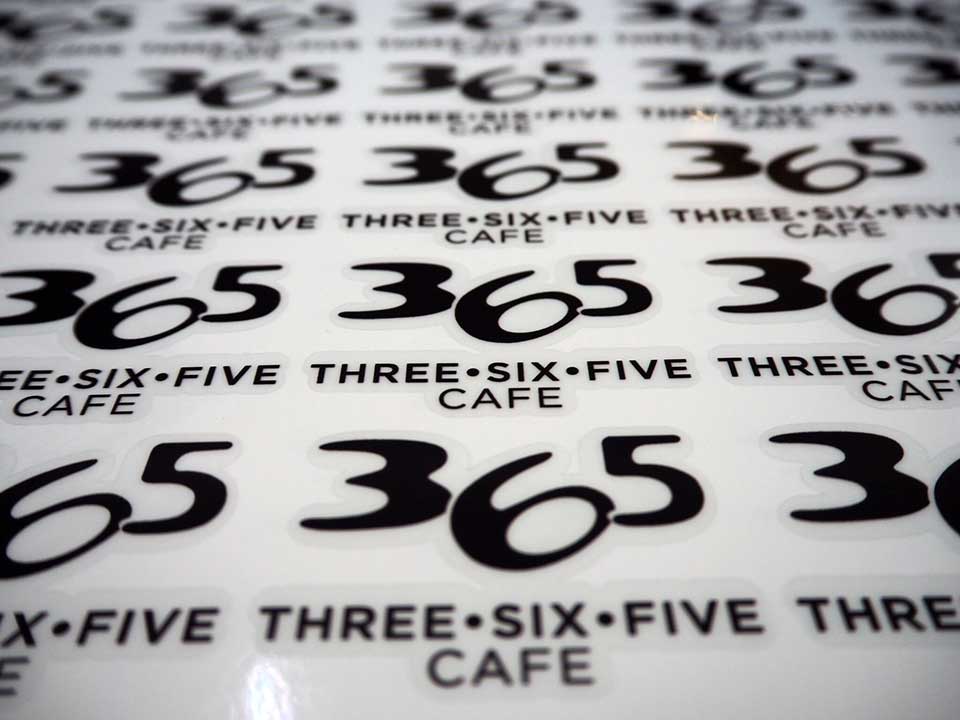

Product Label Printing with Digital Printing Technology

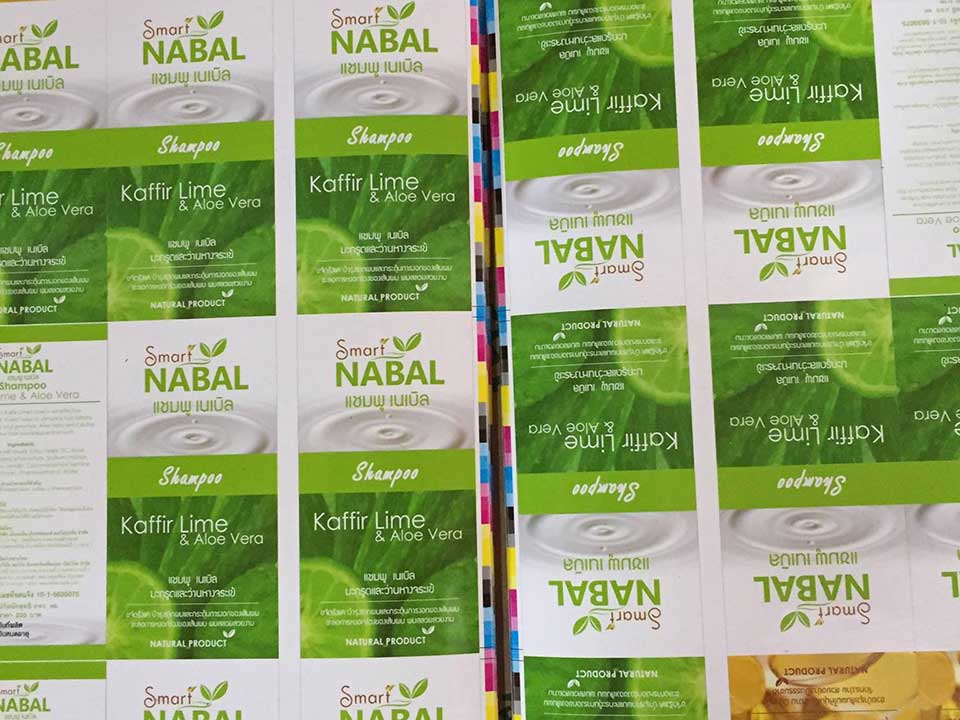

Product label printing using Digital Printing technology has become a popular choice in the label printing industry due to its flexibility and high quality. This method allows for the production of digital printing labels with precise details and customized designs, quickly and efficiently.

Digital Printing Technology for Product Labels

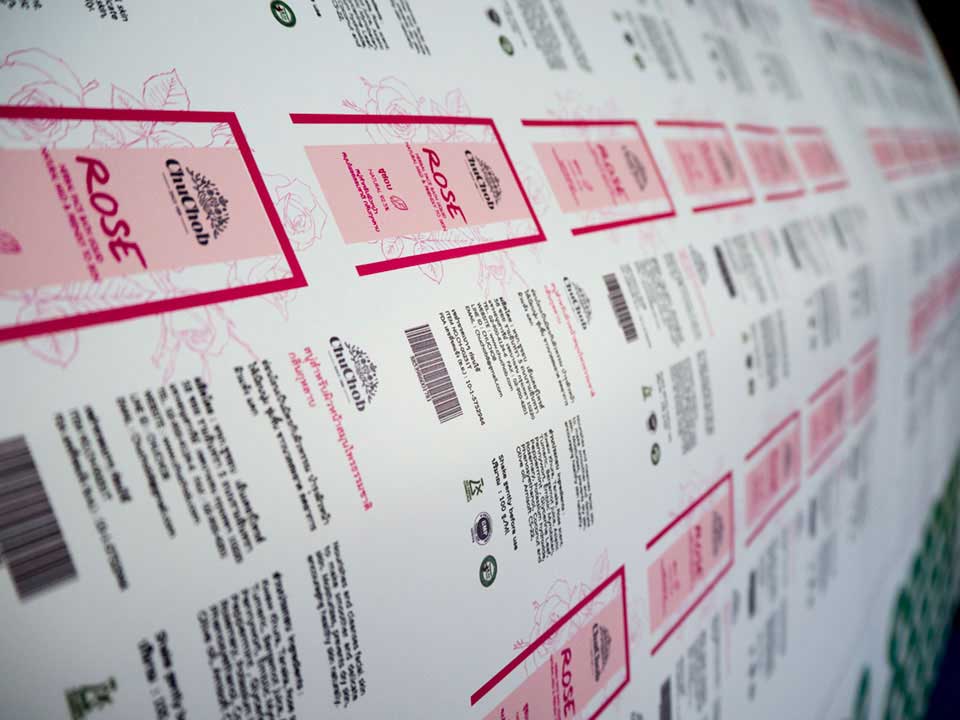

Digital Printing differs from traditional printing methods as it eliminates the need for physical plates. This technology enables the direct transfer of digital files to the printer, allowing for fast and accurate label production.

Some key advantages of Digital Printing for product labels include:

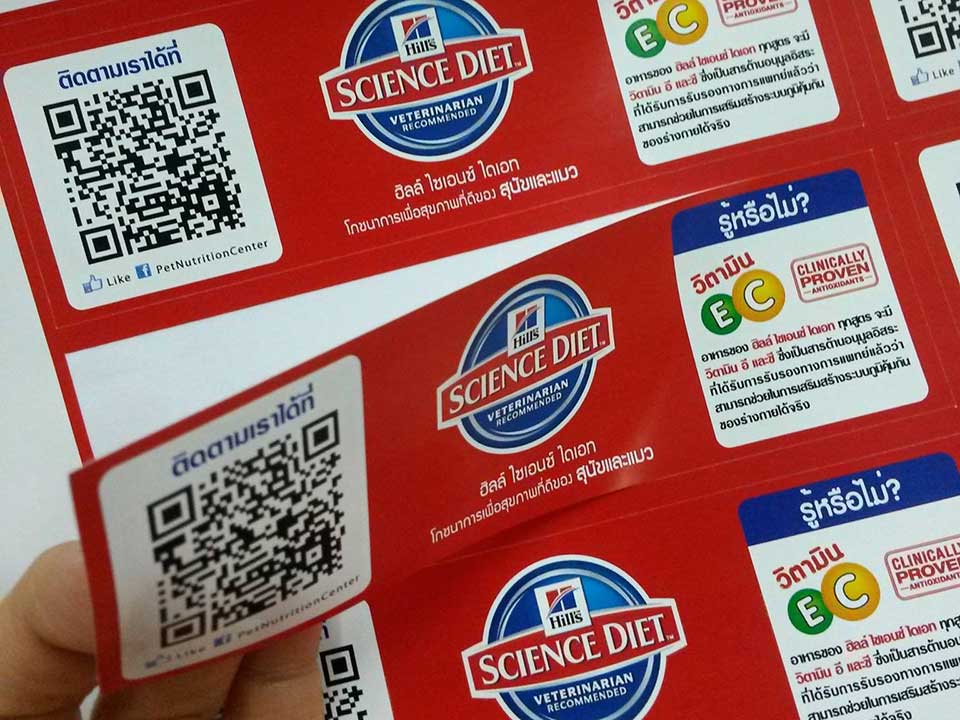

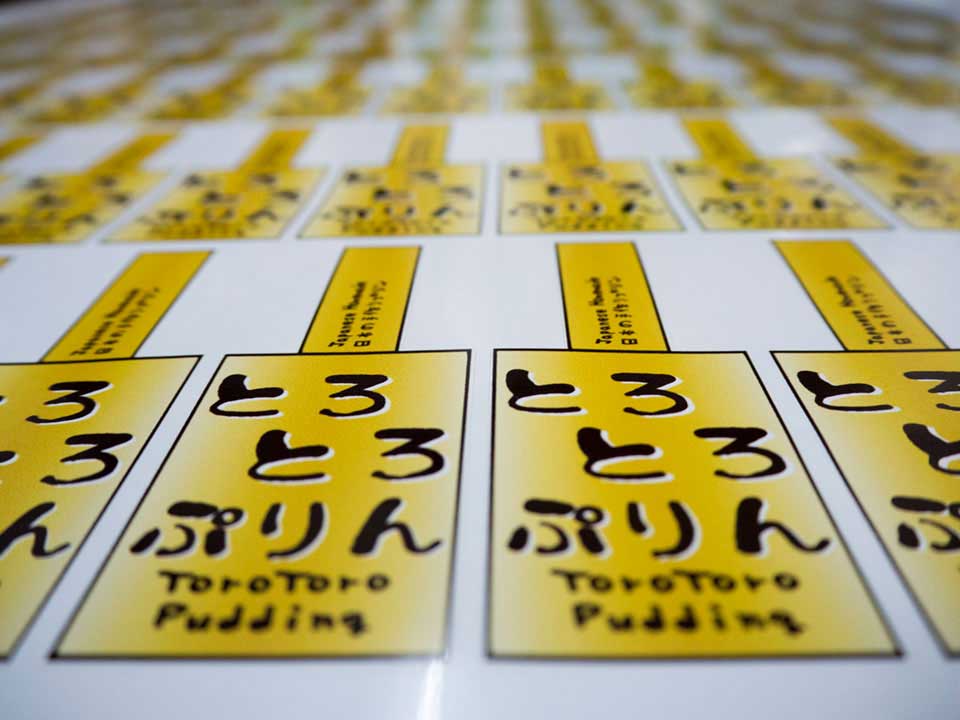

- Print-on-Demand: This method allows for printing labels in the exact quantity needed, with the flexibility to change information or designs quickly for each print run.

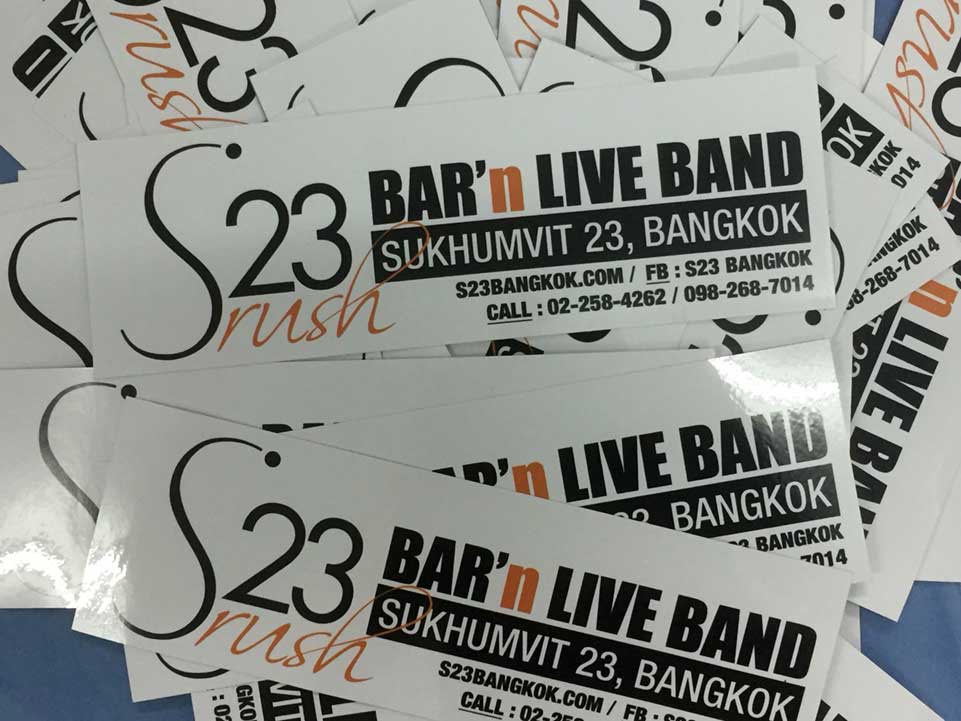

- High Resolution: Digital Printing can produce high-resolution images, resulting in superior label quality with vibrant colors and sharp details.

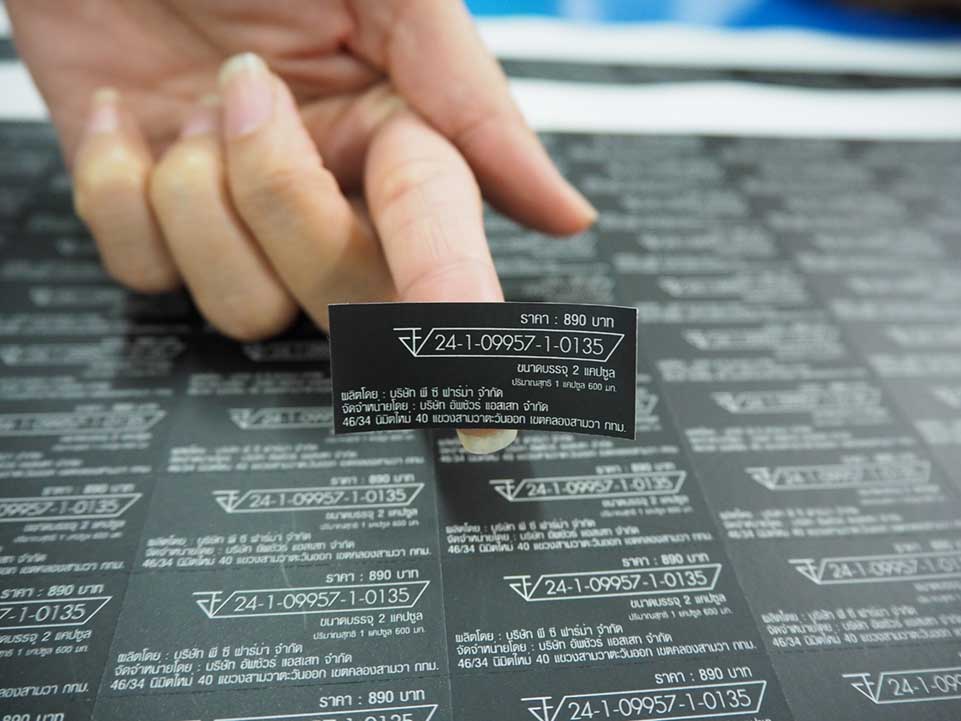

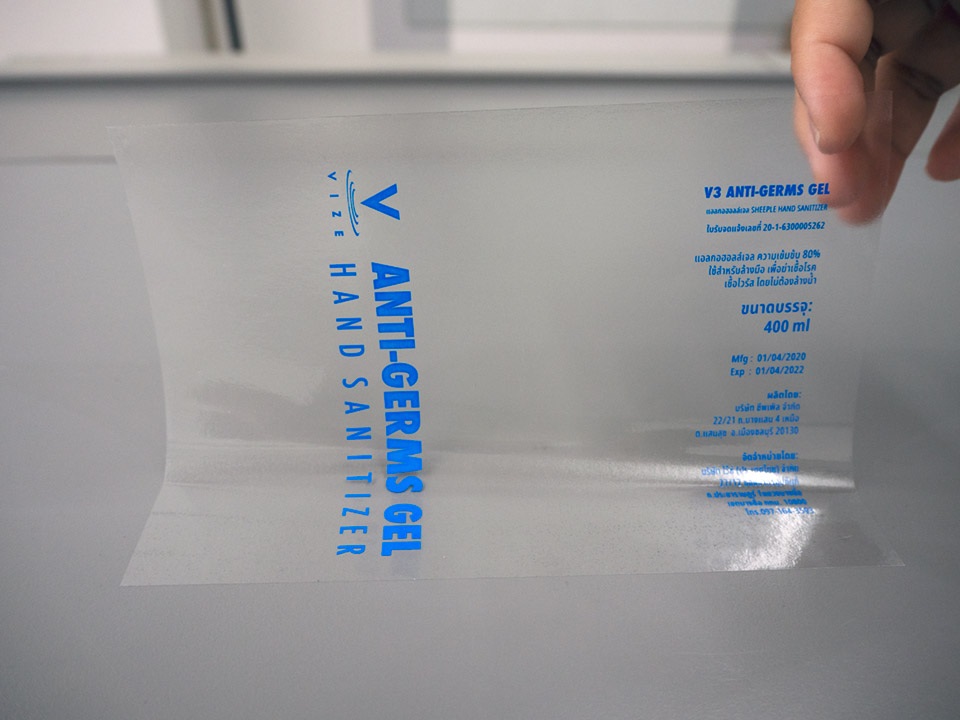

- Easy Data Updates: The technology allows for easy updates to label information, such as changing expiration dates, product codes, or special promotions.

Benefits of Digital Label Printing

The benefits of digital label printing include:

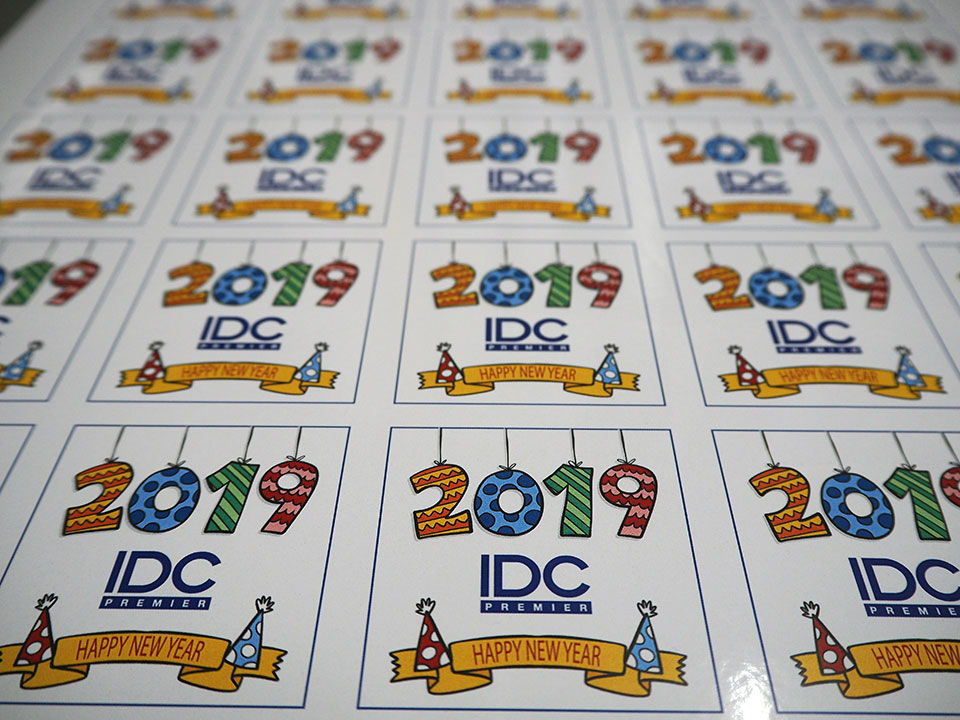

- High Flexibility: Ideal for printing labels that require frequent updates, such as labels for new products or those that need to be altered for seasonal or marketing campaigns.

- Fast Production: Digital Printing requires minimal setup time, allowing for rapid label production, making it perfect for urgent projects or those with short turnaround times.

- Low Cost for Small to Medium Quantities: Without the need for creating physical plates, Digital Printing is more cost-effective for small to medium print runs, eliminating the need for large inventory stock.

Materials Used in Digital Label Printing

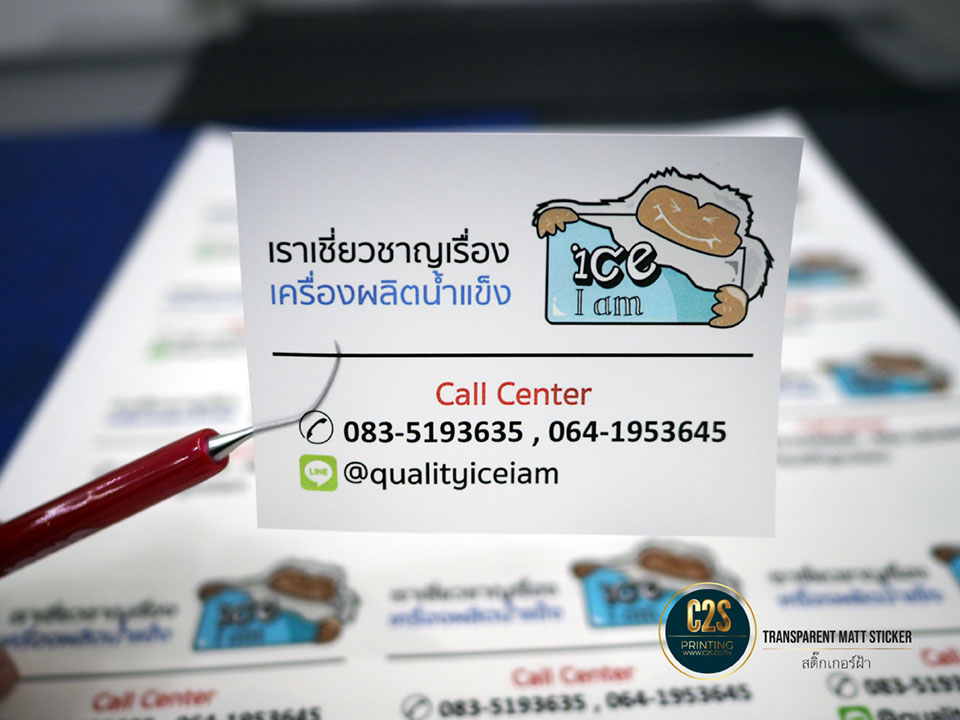

Digital label printing offers a variety of materials to choose from, depending on the product’s needs:

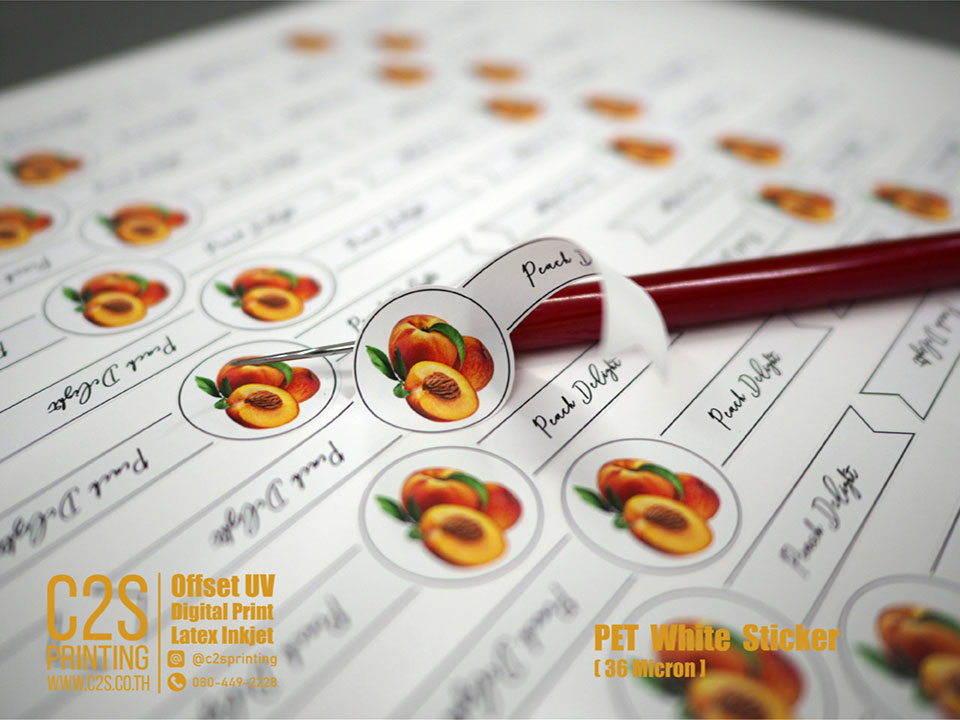

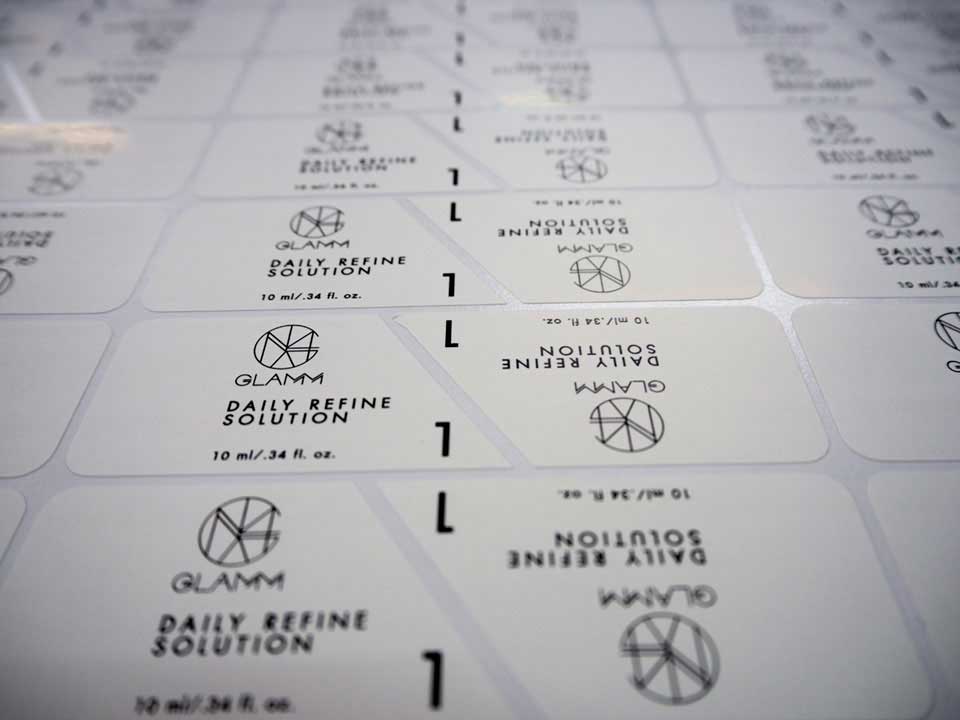

- PET Stickers: These can be printed on high-quality white or clear PET stickers.

- Foil Stickers: Including glossy silver foil, gold foil, and rose gold foil stickers, ideal for products that require a luxurious appearance.

- Glow in the Dark Stickers: Perfect for attracting attention in dark environments or for products needing a special touch.

Choosing the right material for your labels is crucial to achieving the best results. Consider the durability needed for the environment and usage the product will encounter.

Ideal Uses for Digital Label Printing

Digital label printing is ideal for:

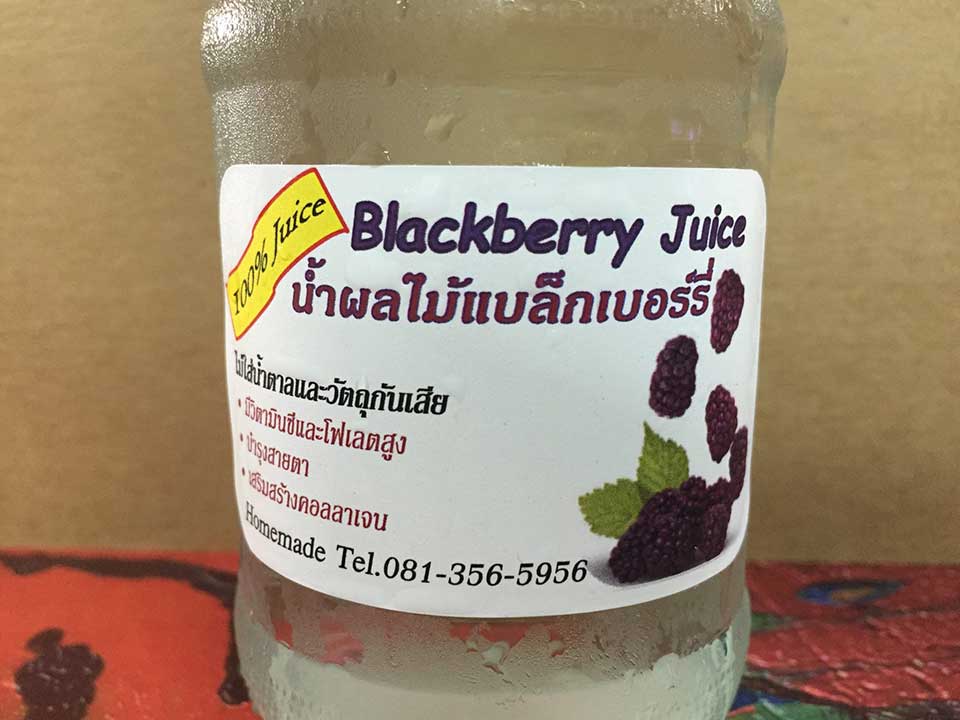

- Seasonal and Limited Edition Labels: Perfect for products requiring specific customization, such as seasonal labels, limited edition labels, or products with special designs.

- Small to Medium Businesses: Suitable for businesses needing to order labels in small to medium quantities.

- Labels Requiring Fast Turnaround: Such as products that need to be quickly brought to market or those that require rapid response to customer demands.

Limitations of Digital Label Printing

The limitations of digital label printing include:

- Higher Cost per Unit for Large Quantities: For large print runs, the cost per unit may be higher compared to traditional printing methods.

- Ink Durability: While digital inks are of high quality, in some cases, they may not be as durable as traditional inks for long-term use or in harsh environments.

Trends and the Future of Product Label Printing

The rapid development of Digital Printing technology continues to expand its capabilities, allowing for more complex and diverse printing options in the future. The growing demand for digital label printing highlights its importance and the convenience it offers in meeting the fast-changing demands of the market.

In summary, Digital Printing for product labels provides a versatile, efficient, and high-quality solution for businesses, especially those needing flexibility and quick turnaround. As the technology evolves, it will likely play an even more significant role in the printing industry, supporting the growing need for customization and rapid production.